How to Create Precision Aluminium Metal Parts?

- 13 Beschädigen, 2023

- 4810 Besuche

Creating precision aluminium metal parts is a complex process that requires specialized knowledge and skills. Aluminium is a popular material due to its low density, high strength, and excellent corrosion resistance. In this article, we will discuss the steps involved in creating precision aluminium parts.

Design

The first step in creating precision aluminium parts is to have a detailed design. This design should include all the required specifications, including dimensions, tolerances, and material requirements. The design will be used to create a 3D model of the part, which will guide the manufacturing process.

The design phase is critical as it sets the foundation for the entire process. The designer must take into account the end-use application of the part, the environmental conditions, and the functional requirements. The designer must also consider the manufacturing process and select the most efficient method to produce the part.

Material Selection

The next step is to select the right type of aluminium for the application. There are many different types of aluminium alloys, each with its own set of properties. Some alloys are better suited for high-stress applications, while others are better for lightweight parts. The selection of the right alloy is crucial to achieving the desired performance.

The designer must consider the properties of the aluminium alloy, including its strength, ductility, and corrosion resistance. The designer must also consider the cost and availability of the selected alloy.

Machining

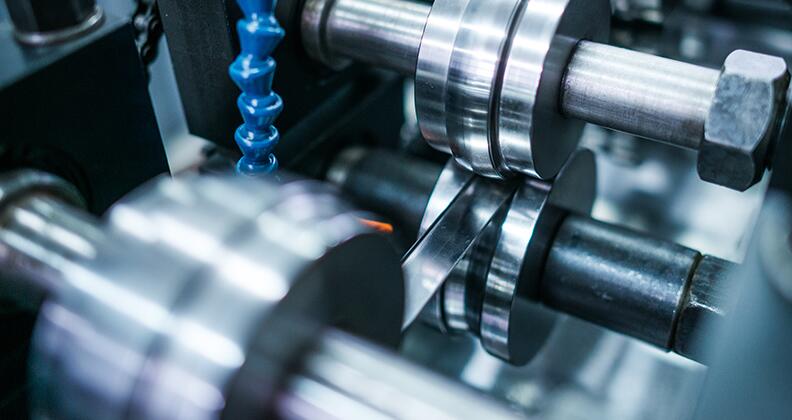

Machining is the process of cutting, shaping, and finishing the aluminium to create the desired part. There are several methods of machining, including milling, turning, drilling, and grinding. Each method has its own advantages and disadvantages, and the choice of method will depend on the part design and the desired finish.

CNC (Computer Numerical Control) machining is a popular method used to create precision aluminium parts. CNC machining is a computer-controlled process that produces precise and complex shapes. It allows for a high degree of accuracy, repeatability, and efficiency.

During machining, the aluminium is held in place using a fixture, and the cutting tool is programmed to remove material in a specific pattern. The machining process is monitored to ensure that the part is within the specified tolerances.

Quality Control

Quality control is an essential step in creating precision aluminium parts. It involves verifying that the part meets all the required specifications, including dimensions, tolerances, and material properties. Quality control can involve various methods, including visual inspection, measuring with precision instruments, and non-destructive testing.

Non-destructive testing methods include X-ray, ultrasonic, and magnetic particle testing. These methods can detect defects that may not be visible to the naked eye. Quality control is critical to ensuring that the part meets the requirements of the end-use application and performs as expected.

Surface Finishing

Once the part has been machined and verified, the next step is to finish the surface. Surface finishing can involve various methods, including polishing, anodizing, painting, and powder coating. The choice of finishing method will depend on the application and the desired appearance of the part.

Anodizing is a common surface finishing method used for aluminium parts. It involves immersing the part in an electrolytic solution and applying an electric current. This process forms a durable oxide layer on the surface of the aluminium, improving its corrosion resistance and enhancing its appearance.

Conclusion

Creating precision aluminium metal parts is a complex process that requires specialized knowledge and skills. The designer must consider the end-use application, the environmental conditions, and the functional requirements. The selection of the right aluminium alloy is critical to achieving the desired performance. CNC machining is a popular method used to create precise and complex shapes. Quality control is essential to ensuring that the part meets the requirements of the end-use application. Surface finishing is the final step in creating a high-quality part that meets the desired appearance of the part.

We provide Precision Aluminum Metal Parts OEM Customization. Contact us for more information.

- Kategorie:

- Kunst & Kultur

- Keine Kommentare