Several joint methods for making abrasive belts

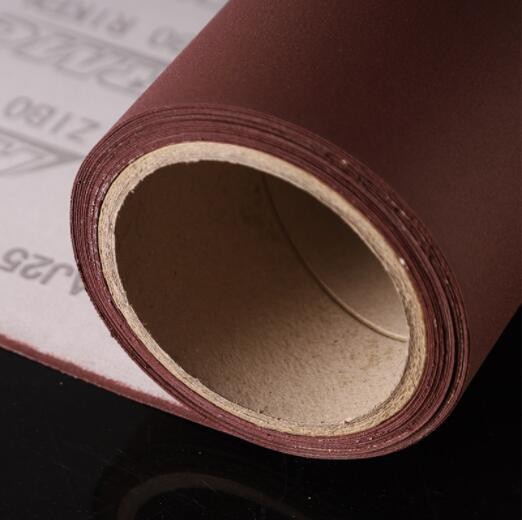

Abrasive belt is a very important variety of sandpaper abrasive belt and abrasive cloth roll. There are usually three categories of hard cloth abrasive belts, soft cloth abrasive belts and paper abrasive belts. As an abrasive belt, it is generally composed of four elements, namely matrix, binder, abrasive and structure. Among them, the structural form of the abrasive belt refers to two forms: "no joint abrasive belt" and "joint abrasive belt".

(1) Jointless abrasive belt

The jointless abrasive belt is a kind of abrasive belt without joints made by using the cylinder cloth as the base and after a series of processes such as original cloth treatment, gluing, sand planting, and curing. This kind of abrasive belt is an early product. Today, only in Japan and my country (including Taiwan) still retain this kind of product, and there are a small number of products. Due to the cylinder cloth substrate, production equipment and limitations used in the belt of this sand process, it cannot meet many specifications on the current market, especially the requirements of wide abrasive belts, and the production efficiency is relatively low and the process is complicated. Therefore, in the modern abrasive belt production exhibition It is eliminated in the middle and replaced by abrasive belts with joints.

(2) There are joint abrasive belts

In the domestic and foreign abrasive belt standards, the word "abrasive belt" actually refers to the joint abrasive belt. There are two types of joint abrasive belts: lap joints and butt joints, from the past lap joints to butt joints. The docking of European and American abrasive belts accounts for more than 75%. The biggest advantage of docking abrasive belts is to avoid the directionality specified in the use of overlapping abrasive belts.

1. Lap method abrasive belt

The lap joint method is two joints. According to the determined width requirements, the sand surface and the cloth surface are respectively ground into inclined edges (usually a 67-degree oblique angle), coated with joint glue, and then superimposed and pressed together. The thickness after superimposition, that is, the thickness of the joint, cannot be greater than 0.1mm of the thickness of the non-joint. This joint method has been widely used at home and abroad, whether it is cloth base, paper base or even composite base.

2. Butting method abrasive belt (flat connection)

The butt abrasive belt is to first grind the front (sand surface) or back (cloth surface) of the two joint edges, and the thickness of the grinding is equal to the thickness of the joint pad, and then paste a PVC mylar film at the joint and press it. made of abrasive belts. This film is not only strong but also has very little elongation. Butt joint is a widely used joint method. It is simpler in process, stable and smoother than the lap joint method, but the cost will be higher (currently domestic PVC materials are usually charged at 4-5 yuan/meter). fee). At present, the PVC films used in domestic abrasive belt factories are divided into five color joint films: yellow, red, white, blue and green, with specific technical properties, different orientation angles, and different film thicknesses to meet the needs of different abrasive belts.

The docking method is divided into two forms: one is the general butt joint, that is, the direct splicing of the two joints (ordinary butt joint), and the other is the S-shaped butt, that is, the two joints are processed into S-shaped sides, and then two The S-shaped edges are engaged with each other like gears, and the PVC mylar film is added to form an abrasive belt (S-shaped flat joint).

- Category:

- News

- 24 May, 2022

- 1733 views

- No comments