How to choose the right automatic foil stamping machine for your production needs?

With the development and application of automation technology, automated hot stamping machines have become one of the most important pieces of equipment on modern production lines. Automated foil stamping machines can greatly improve production efficiency, reduce labour costs and increase the quality and added value of your products. However, different production needs and product characteristics require different types of automated hot stamping machines, so it is vital to choose the right automated hot stamping machine for your production needs. This article will explain how to choose the right automatic foil stamping machine for your production needs.

1. Understanding product characteristics and production needs

Before choosing an automated foil stamping machine, you first need to understand the characteristics of your product and production needs. For example, what material is the product to be stamped on? Where will the stamping take place? What is the size of the pattern and text to be stamped? What is the quantity of product to be produced and at what production speed? All these questions will influence the choice of the type and specification of the automatic foil stamping machine.

2. Understanding the types and specifications of automated foil stamping machines

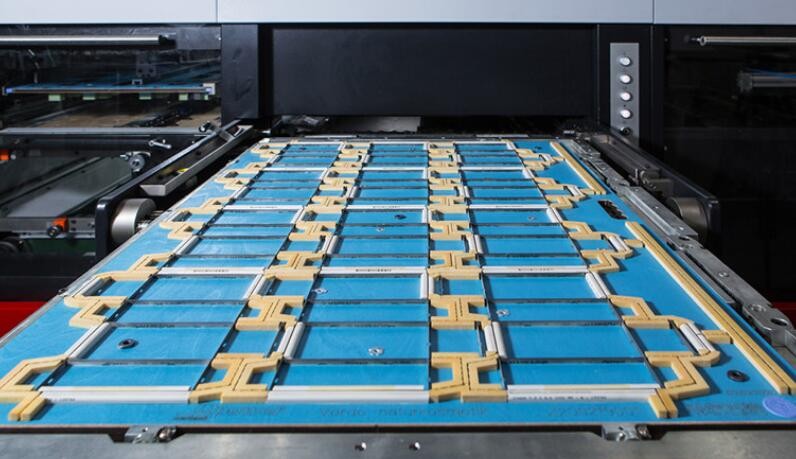

There are various types and sizes of automated foil stamping machines, such as flat foil stamping machines, roller foil stamping machines and multi-functional foil stamping machines. Flat stamping machines are suitable for stamping flat products such as paper, plastic sheets etc. Roller stamping machines are suitable for stamping round and irregular shaped products, such as bottles, tubes etc. Multifunctional stamping machines are suitable for a wide range of shapes and materials. In addition, different automated foil stamping machines have different specifications and performance, such as maximum stamping area, stamping temperature range, production speed, etc.

3. Choose a reliable hot stamping machine manufacturer

Choosing a reliable hot stamping machine manufacturer is an important guarantee of product quality and after-sales service. Reliable hot stamping machine manufacturers usually have rich production experience and a professional technical team, which can provide users with comprehensive technical support and after-sales service. In addition, a reliable hot stamping machine manufacturer will usually provide a customised solution for the user, offering the most suitable automated hot stamping machine according to the user's production needs and product characteristics.

4. Consider the degree of automation and ease of operation

Different automatic foil stamping machines have different levels of automation. Generally speaking, the higher the level of automation, the more efficient the production, but also the more expensive. It is also important to consider the ease of operation, as some automated foil stamping machines require professional technicians to operate, while others are relatively simple and can be operated by operators.

5. Consider cost and value for money

Choosing the right automatic foil stamping machine for your production needs requires consideration not only of the price of the machine itself, but also of the maintenance and operating costs of the machine. Some machines are very expensive to maintain and operate and require a large investment over time, while others are relatively inexpensive. When choosing an automated foil stamping machine, it is important to consider its cost effectiveness and choose the most suitable machine.

In conclusion, choosing the right automated foil stamping machine for your production needs requires consideration of a number of factors, including product characteristics and production requirements, the type and specification of the foil stamping machine, a reliable foil stamping machine manufacturer, the degree of automation and ease of operation as well as cost and value for money. Only by considering all these factors can you choose the most suitable automation for your needs.

- Category:

- Business

- 5 Apr, 2023

- 1137 views

- No comments